Case Study

Unsupervised energy consumption and little tracking of data led

to increased energy consumption and operating costs in a

manufacturing plant.

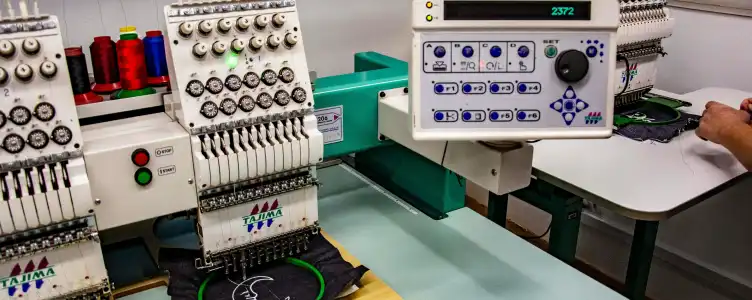

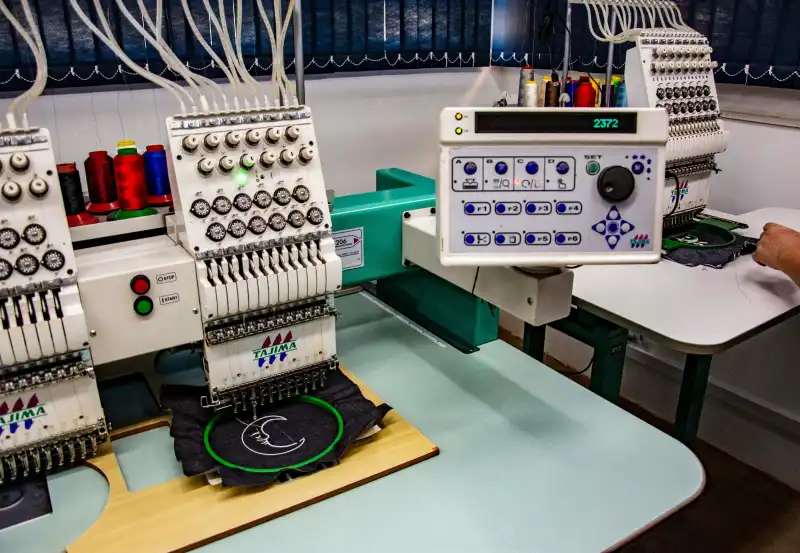

A manufacturing unit was facing myriad issues due to energy management operations with insignificant automation. Low supervision of energy consumption, unavailability of usage limit mechanisms, and little tracking of data, which led to unexpected breakdowns and maintenance were some of the problems they faced. It increased their energy consumption and operating costs.

SpringCT understood their existing system and pain points and suggested integrating our in-house energy management platform, Inspec EMS. Transforming a legacy system into an advanced and smarter IoT-enabled energy management system was a challenge in itself. SpringCT with its significant experience, developed a system for clients that reduced energy management and operational costs. The new system was designed to give customers more visibility into their energy consumption, allowing them to identify areas of waste and inefficiency.

A manufacturing unit was facing myriad issues due to energy management operations with insignificant automation. Low supervision of energy consumption, unavailability of usage limit mechanisms, and little tracking of data, which led to unexpected breakdowns and maintenance were some of the problems they faced. It increased their energy consumption and operating costs.

SpringCT understood their existing system and pain points and suggested integrating our in-house energy management platform, Inspec EMS. Transforming a legacy system into an advanced and smarter IoT-enabled energy management system was a challenge in itself. SpringCT with its significant experience, developed a system for clients that reduced energy management and operational costs. The new system was designed to give customers more visibility into their energy consumption, allowing them to identify areas of waste and inefficiency.

Product Features

-

Data AcquisitionAcquire energy consumption data from energy meters using Modbus protocol for real-time monitoring.

-

Multi-timeframe AnalysisAnalyse hourly, shift-wise, daily, weekly, quarterly, and annual energy consumption patterns for comprehensive insights.

-

Smart Alerting SystemGenerate alarms for exceeded threshold values of parameters like voltage, current, PF, demand, consumption etc.

-

Admin ConsoleAdmin console to add users and to set access rights as per the organization requirements for secure system management.

Key Technical Achievements

-

Designed and implemented a highly modular energy management system for scalability and maintainability.

-

Centralized secure access to energy consumption information with role-based permissions and security.

-

Historical data analysis to view patterns and compare average vs current trend for predictive insights.

Technologies Used

- React JS: Modern JavaScript library for building responsive and interactive user interfaces.

- TSDB (Time Series Database): Specialized database for storing and analyzing time-series energy consumption data.

- Modbus Protocol: Industrial communication protocol to acquire data from energy meters and sensors.

- IoT Platform: Advanced IoT-enabled energy management system for real-time monitoring and control.

- Inspec EMS: SpringCT's in-house energy management platform for comprehensive energy monitoring and optimization.

Results

- Successfully reduced energy wastage through intelligent monitoring and control systems

- Direct positive impact on operational cost through optimized energy consumption

- Ability to predict consumption based on historical patterns and trends

- Improved energy efficiency and reduced unexpected breakdowns

- Enhanced visibility into energy consumption patterns for better decision-making

Conclusion

SpringCT helped reduce energy cost by monitoring,

managing & controlling energy demand resulting in

improved energy efficiency by reducing wastages. The

plant could also set benchmarks and specific performance

indicators after looking at energy patterns over a

period of time. The transformation from a legacy system

to an advanced IoT-enabled energy management system

demonstrated SpringCT's expertise in delivering

innovative solutions that drive significant operational

improvements and cost savings.